-

On Mars:

Exploration of the Red Planet. 1958-1978

-

-

-

- WORKING TOWARD JULY

1975

-

-

-

- [192] Money problems would always haunt

the Viking project. The scarcity of dollars especially affected

the development of the lander and its science payload and

repeatedly tried people's patience and equanimity. Early in 1973,

Joseph R. Goudy, the Langley Viking Project Office resident

engineer at JPL, commented on budget cuts that led to the

dismissal of about 200 employees at the California laboratory on

rather short notice:

-

- These cutbacks have created a different

atmosphere and environment, resulting in a change in attitude. Six

months ago, when the [Viking Project Office] came in with a new

requirement or direction that required additional or premature

effort, it was generally accepted with the attitude. "We don't

think it's necessary but it's their money; if they want it, we'll

do it." Now, with the Orbiter having to take rather severe cuts,

this is no longer considered "their" money and the attitude has

become much more critical. if not down-right hostile.

66

-

- Henry Norris, looking for ways to keep his

orbiter personnel from reacting too negatively to the repeated

budget cuts, tried to convince them-and for the most part he

succeeded-that the budget was just one of the many realities that

a good engineer or manager had to live with and work around as he

tried to do his job.

-

- The tasks assigned to the orbiter teams

were laid before them in a five-year schedule, which ended with a

pair of mid-summer 1975 launches. The master plan was presented

for the first time at the Viking Project Management Council

meeting in February 1970, and it reflected the changes brought by

the stretchout.

-

- The pace of the work at JPL assumed a

rhythm familiar to the people who had worked on other NASA

projects. The determining factors, "drivers"....

-

|

Table 33 [193]

|

|

Viking Orbiter

Schedules

|

|

|

|

Event

|

Proposed before

|

Proposed after

|

Actual

|

|

1 Jan. 1970

|

1 Jan. 1970

|

Dates

|

|

|

|

Preliminary design review

|

May 1970

|

Jan. 1972

|

19-20 0ct. 1971

|

|

Critical design review

|

June 1971

|

Jan. 1973

|

9-lO July 1973

|

|

Start proof-test spacecraft

test

|

Aug. 1972

|

March 1974

|

Jan. 1974

|

|

Qualification test completed

|

Nov. 1972

|

July 1974

|

Jan. 1975

|

|

Shipment of first flight hardware to

KSC

|

Feb. 1973

|

Dec. 1974

|

Feb. 1975

|

|

Launch

|

July 1973

|

July 1975

|

20 Aug. 1975

|

|

|

|

|

9 Sept. 1975

|

SOURCE: Information on the 1970 master plan

was awaken from Henry Norris, "Viking Orbiter Project Staff Meeting-

Minutes of January 13 and 14, 1970," memo, 19 Jan. 1970.

-

-

- ....in NASA parlance, for the designers

and engineers were master schedules that determined when major

hardware components had to be completed so the launch dates could

be met. But the realities of designing and building the spacecraft

did not always conform to calendar milestones, and the variance

led to frequent revisions of the schedules. At every step along

the way, the work was formally documented in a large number of

Viking project documents. By cross-checking and coordinating these

documents, the project manager at Langley could be assured that

the orbiter, lander, science payloads, launch vehicles, ground

support equipment, flight control facilities, and the tracking

system would all function as required when the hardware was

brought together and assembled for the launch and flight to Mars.

This system of mass documentation, formal reviews, telecons, and

informal conversations worked because the people associated with

the effort believed in delegated management. Jim Martin's

centralized responsibility and authority for Viking was a key

factor to the project's success, but equally important was the

esprit de corps among the Viking teams at the working level.

67

-

- The troops at JPL functioned within

divisions responsible for specific engineering activities or

disciplines. Norris and his orbiter staff allocated funds,

prepared plans and schedules, assigned tasks, and received

progress reports, but the divisions carried out the actual design

and development of the spacecraft and experiment hardware, as well

as prepared and operated such facilities as the Deep Space Network

and the Space Flight Operations [194] Facility. Each division

chief and his subordinates not only supervised their personnel but

also selected the engineers who represented their divisions on the

orbiter team.*

68

-

- The structure of management at JPL did not

fit Jim Martin's management scheme. The people at Langley had

always worked through a more centralized organization, in which

everyone was directly responsible to the project director, and the

Viking Project Office was uneasy with the JPL system. Martin knew

that the organizational structure of the lab would not likely be

changed just for this mission, so he went to Pasadena in the early

spring of 1970 to observe firsthand how JPL worked. Specifically,

he wanted to know: How had JPL dealt with hardware problems in the

past? How did it plan to manage the Viking orbiter in the future?

How would it control the flight phase of a mission?

69

-

- Henry Norris believed that the time Martin

spent with division managers and Viking representatives at JPL led

him to understand more clearly the lab's approach to project

management. Martin was still "not entirely comfortable" with the

organization, Norris reported, but at least the project director

had been exposed to it and the men who filled the ranks. Likewise,

the people at JPL began to appreciate the sources of Martin's

concerns and continued to work with the project office to improve

and strengthen JPL management control over the teams in Pasadena.

70

-

- Although they had adopted different

approaches, the personnel at Langley and JPL were working toward

the same goal. Once the baseline orbiter configuration had been

established in February 1969, the next major orbiter goal was the

preliminary design review (PDR). This formal review, held on 19-20

October 1971, came at the end of the conceptual phase for the

design of the orbiter systems; the specialists were now ready to

work on the detailed design of the hardware. Once the basic

soundness of all aspects of the orbiter was approved, the teams

would head for the next important milestone, the critical design

review (CDR). Getting to the PDR had been a major accomplishment.

made difficult by the repeated problems with the budget; but the

teams at JPL had completed their design work and coordinated their

efforts, attending weekly meetings and frequently using the

telephone along the way. In fact. more than 60 meetings were held

that directly impinged upon the design of the orbiter.

-

- The preliminary design review gave all

interested parties a look at the orbiter as JPL planned to build

it. Once the conceptual design was complete, work on the design of

breadboards, or first working test models, of the basic orbiter

subsystems would begin. These designs would be evaluated at

subsystem PDRs an once approved, work on e breadboards would [195]

proceed, with their suitability for conversion into flight

hardware being confirmed during a series of subsystem critical

design reviews. A general A general CDR for the entire Viking

orbiter system would certify the readiness of the orbiter staff to

go to the next step-building the flight-ready orbiters.

-

- By October 1971, the orbiter had assumed

the basic configuration it would have when launched in 1975. The

spacecraft had grown considerably larger than its Mariner Mars 71

predecessor. Most noticeable visually were the larger solar panels

and the larger high-gain antenna. But all the internal subsystems

were taking on a Viking identity of their own as well. The Mariner

inheritance was still there, but instead of directly transferring

subsystems from one craft to another, the engineers were borrowing

from Mariner experience and know-how. Still, it was this transfer

of technological knowledge from Mariner Mars 71 and Mariner Venus

73 that permitted the Viking orbiter personnel to get the craft

ready to fly on time with a minimum of problems and money

crises.

-

- Jack Van Ness, deputy Viking project

manager, recorded in his "Viking Weekly Highlights Report" that

the orbiter system preliminary design review was well organized

and informative. Only 22 action items remained for solution. "This

relatively small number is somewhat indicative of the clarity and

thoroughness of the presentations." At the conclusion of the

review, the Viking Advisory Review Panel and the Orbiter System

Manager's Advisory Panel provided a favorable overall evaluation

of the orbiter status. None of the evaluations turned up any

critical problems that would give Martin's Viking Project Office

cause for concern. 71

-

- With the PDR behind them, Norris's people

began to prepare the detailed designs of the 21 orbiter

subsystems. Soliciting requests for proposals from industrial

contractors, selecting companies to build the subsystems, and

negotiating contracts occupied the months from October 1971 to

July 1972. One contract was not let until July 1973. Meanwhile,

the various divisions at JPL bad begun to work on the subsystems

that would be built at the laboratory. Preliminary design reviews

for these subsystems began in January 1972 and lasted until late

November.

-

- Close on the heels of the PDRs came the

subsystem critical design reviews, which spanned January to July

1973. When the subsystem CDRs were completed, a general CDR at JPL

9-10 July 1973 evaluated the entire orbiter system as it had

evolved to date. The CDR panel, the Viking Advisory Panel, and the

Orbiter System Manager's Advisory Panel all expressed their

confidence in JPL's performance and the quality of the teams'

work. 72 The technical problems being encountered by the

orbiter were the routine kind that appeared during the course of

most spacecraft projects-recurring difficulties with poor-quality

integrated circuits and an unhappy experience when an early

production propulsion tank ruptured because of a metallurgical

failure.

-

- During the summer of 1973, only two

subsystems caused genuine concern. The infrared thermal mapping

(IRTM) subsystem was behind [196] schedule, but by mid-July the

Santa Barbara Research Center had the trouble under control, and

the subsystem CDR was held that month. The data-storage-subsystem

tape recorder's failure to operate at a satisfactory speed put it

on the Viking Project Office's "Top Ten Problems" list. In October

the "54L" integrated circuits were also added to the list.

Overall, however, the orbiter was shaping up as a well-behaved

spacecraft, and everyone was pleased. Concern over the orbiter's

financial problems was constant, but the project management was

confident that Henry Norris's teams were on schedule and doing

well. By drawing on Mariner heritage, they had the Viking orbiter

under control. 73

-

- In mid-1973, the orbiter hardware entered

the test phase. The first test, called the modal test, was

conducted with the orbiter development test model, to determine if

the mathematical model used for the engineering load analysis was

correct. The modal test ran from late May until the end of July. A

week later, General Electric delivered the first computer command

subsystem. In late August, the propulsion-system engineering test

model was test-fired at the NASA Edwards Test Station in

California, while at JPL the flight-data-subsystem breadboard was

checked out with other pieces of hardware that were to be linked

to it, such as the visual imaging subsystem, the IRTM, and the

atmospheric water detector. During the first and second week of

September, other tests were run to determine the effect of shock

on various orbiter instruments. Joseph Goudy reported to Martin on

the 14th that the results from the pyrotechnic shock tests were

much better than they had anticipated: "None of the subsystems

that were on board for the tests appeared to have suffered any

adverse effects." The sensitive instruments would not be harmed

when the spacecraft was explosively separated from the Centaur

launch vehicle stage and the lander was explosively separated from

the orbiter. 74 In mid-December 1973, JPL completed the vibration

stack test of the orbiter and lander development test models.

Since this was the first time that orbiter and lander hardware had

been mated and tested together, everyone in Pasadena was

particularly satisfied when no important questions were raised by

the examinations. 75

-

- With the new year upon them, the orbiter

team focused its attention on final assembly of the proof-test

orbiter and tests of this first flight-style hardware. These

qualification tests would determine the spaceflight worthiness of

the orbiter system designs as they had been rendered into

hardware. The assembly process took three months as each of the

subsystems was checked out and assembled onto the orbiter bus.

During April and May, the engineers at JPL conducted the system

readiness test, verifying the functioning of all orbiter

components. The successful examination of the orbiter hardware

prompted Goody to report to the Viking management at Langley that

they were on schedule and that the assembly of the proof-test

orbiter had served as a "pathfinder" for the fabrication of the

flight orbiters. 76 In the process of building this first craft,

officially designated Viking orbiter 1 (VO-l), the spacecraft

assembly personnel members at JPL learned some....

|

Table 34 [whole

page 197]

|

|

Growth in Capacity of Data

Storage Subsystems

|

|

|

|

|

Mariner 64

|

Mariner 69

|

Mariner 71

|

Viking 75

|

|

|

|

Number of tape

recorders

|

1

|

1

|

1

|

2

|

|

Number of tracks

|

-

|

4

|

8

|

8 x 2

|

|

Recording rate

|

-

|

16 200 bits per sec

|

132 000 bits per sec

|

301 172 bits per sec, tracks1 through

7; 4 and 16 kilobits per sec, track 8

|

|

Playback rate

|

81/3 bits per sec

|

270 bits per sec

|

1, 2, 4, 8, or 16 kilobits

|

1, 2, 4, 8, or 16 kilobits

|

|

Storage capacity

|

5.4 million bits

|

23 million bits

|

180 million bits

|

640 million bits x 2

|

|

Length of tape

|

100 meters

|

111 meters

|

168 meters

|

384 meters x 2

|

|

Weight

|

-

|

19 kg

|

11 kg

|

7.7 kg x 2

|

|

Contractor

|

-

|

Lockheed Electronics Co. Inc.,

Plainfield, N.J.

|

Lockheed Electronics

|

Lockheed Electronics

|

NOTE: The data subsystems (reel-to-reel tape

recorders) used on the Mariner and Viking spacecraft permitted

recording scientific data and sobsequently playing it back through

the communications subsystem for transmission to Earth. As the number

of experiments increased and the amount of data to be stored and

played back grew, successive data storage systems became more

complex. Each new tape recorder had greater capacity, posing new

technological challenges. In Viking, each data subsystem rape

recorder weighed 3.3 kg less than the Mariner 71 data subsystem

recorder, while having 3.6 times the information storage

capacity.That accomplishment took time and caused some real headaches

for the Viking managers, but the completed recorders worked very

successfully during the missions.

-

- [198]....important lessons that would help

them build Viking orbiter 2 and 3, the orbiters that would fly to

Mars. One problem they encountered was the lack of sufficient work

stands, particularly during the installation of the thermal

insulating blanket. More stands were ordered, to avoid any

bottleneck during the assembly of the flight articles. The

proof-test orbiter was moved on 8 May from the Spacecraft Assembly

Facility to the Environmental Laboratory, where it would go

through the rigors of vibration, electromagnetic interference,

pyrotechnic, thermal vacuum, and compatibility tests during the

summer of 1974. At the same time, engineers would begin assembling

and testing VO-2 and VO-3. 77

-

- On schedule with satisfactory results, the

VO-1 tests were completed in late August. As the JPL team turned

its attention to readying VO-3 for early examination, however,

unexpected budget problems brought a change in plans.

78 On 27 September, the orbiter staff was forced to

order all testing of the third orbiter to cease. The second test

team was disbanded; no money was available for testing. VO-3 was

put into storage, and the proof-test orbiter (VO-1) was

redesignated a flight unit. VO-1 and VO-2 would be the....

-

-

-

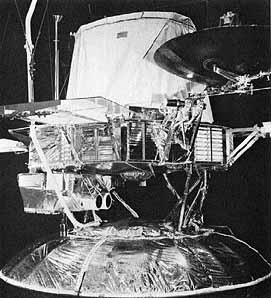

- The thermal-control model of the Viking

orbiter mated to the lander thermal-effects simulator was used in

August 1973 to verify the effects solar radiation would have on

the spacecraft. The science platform with imaging system and other

instruments is attached under the orbiter.

-

-

|

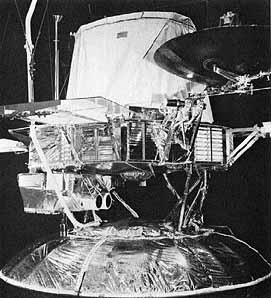

[199] Building the Viking

Orbiter at Jet Propulsion Laboratory in 1974. Men working

inside the chassis, right, fabricate the orbiter bus

structure. Below right, they attach the propulsion module

to the propellant tanks. Below, solar panels are in place

on the nearly completed orbiter.

|

|

|

|

|

-

-

- [200]....spacecraft sent to Mars. To

ensure the acceptability of the proof-test hardware for flight, a

series of meetings were held during the next several weeks.

79 But an orbiter design qualification review

scheduled for early October 1974 lost much of its significance,

since the change in plans had thrown off JPL's timing. As one

participant observed, it was hard for a review panel "to determine

if the Orbiter met all of its requirements in spite of all the

testing that has been done." 80

-

- After several more months of work, orbiter

VO-1 was verified for flight on 9 January 1975, and the VO-2 tests

were completed on the 31st. The orbiters were shipped to the

Kennedy Space Center in February, where a series of preflight

checks would be made through the spring and summer.

81 The Viking orbiter, remarkably close to early

weight predictions (see table 35), was a very carefully tested

piece of equipment. For the teams at JPL, the design, development,

fabrication, and assembly had, for the most part, gone according

to plan, schedule, and budget.

-

|

Table 35

|

|

Viking Orbiter

Specifications, 1969-1975

|

|

|

|

Orbiter Element

|

Baseline Orbiter

|

PDR Orbiter

|

Flight Orbiter

|

|

Feb. 1969

|

Oct. 1971

|

Feb. 1975

|

|

|

|

Bus dimensions:

|

|

|

|

|

- Long sides

|

-

|

-

|

139.7 cm

|

|

- Short sides

|

-

|

-

|

50.8 cm

|

|

- Height

|

45.7 cm

|

45.7 cm

|

45.7 cm

|

|

|

|

Distance from launch vehicle

attachment points to lander attachment points

|

-

|

3.29 m

|

3.29 m

|

|

|

|

Distance across extended solar

panels, tip to tip

|

7.80m

|

9.75 m

|

9.75 m

|

|

|

|

Weight with fuel

|

2298.6 kg

|

2304.3 kg

|

2324.7 kg

|

|

|

|

Weight of fuel

|

1862 kg

|

1404.8 kg

|

1422.9 kg

|

|

|

|

Weight of science instruments

|

57.6 kg

|

65.4 kg

|

65.2 kg

|

|

- Visual imaging system

|

21.8 kg

|

42.05 kg

|

40.05 kg

|

|

- Infrared thermal mapper

|

13.6 kg

|

7.48 kg

|

9.30 kg

|

|

- Mars atmospheric water

detector

|

-

|

15.90 kg

|

15.90 kg

|

SOURCE: JPL "Viking Project Orbiter System,

Visual Presentation, February 13, 14, 1969''[Feb.1969]; JPL "Viking

73 Project Orbiter System PDR, October 19-20,1971, Presentation

Material ' [Oct.1971]; and Martin Marietta Aerospace, Public

Relations Dept., The Viking Mission to Mars (Denver, 1975).

pp.III-25,III-27,III-32,III-33.

-

-

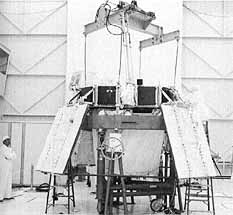

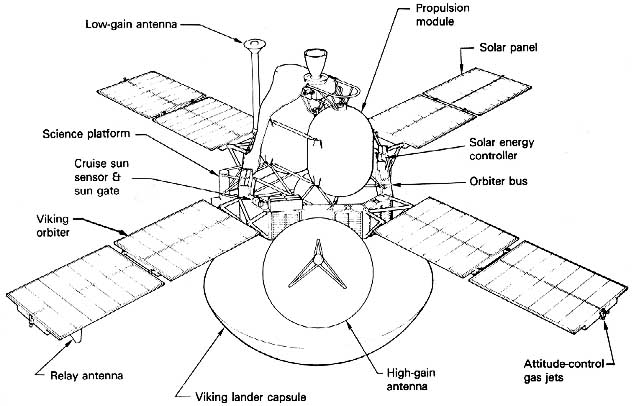

- [201] Configuration of the mated Viking orbiter and

capsule in cruise mode.

-

-

-

- [201] Carl D. Newby, supervisor of the

Spacecraft Development/Mechanical Support Group, oversaw the

assembly of the orbiters. It was the biggest spacecraft Newby and

his team had built, and because it was so big it was an easy craft

on which to work-they had room to move around during the assembly

process. Newby pointed out that it requires a special personality

to work on space hardware and a special dedication. Fabricators

come to view the spacecraft as part of their lives, to care about

it. Working in a closed environment, they have to learn to live

with one another, as well. Spacecraft builders must be adaptable,

very careful, and thoughtful. One false move, one thoughtless

motion can destroy an assembly or component worth thousands of

dollars or months of time. Damage to a spacecraft usually also

requires requalification of the injured components or perhaps

requalification of the entire craft. Workers on the Viking

orbiters-many had worked on Ranger most had worked on the

Mariners-were very fond of their spacecraft.As Newby repeatedly

reminded the specialists at JPL, the orbiter was a "good

spacecraft to work on, it was on time and on budget."

82 Building the Viking landers, however, was a

completely different story.

-

-

* Divisions and their representatives assisting the

Viking orbiter staff at JPL, spring 1970: Quality Assurance and

Reliability, G.E. Nichols; Project Engineering, V.R. Galleher;

Data Systems, G.F. Squibb; Space Science, M.T. Goldfine;

Telecommunications, J.R. Kolden; Guidance and Control, A.E.

Cherniack; Engineering Mechanics, W.J. Carley; Astrionics, J.D.

Acord; Environmental Sciences Simulation, N.R. Morgan; Propulsion,

W.J. Schatz; Mission Analysis, P.K. Eckman; and Technical

Information and Documentation, S.B. Hench.

-

-