|

|

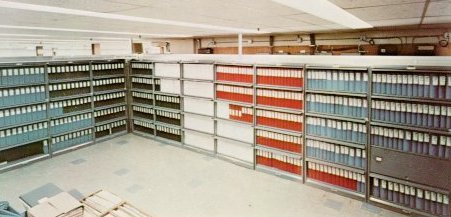

| The pedigree of just one Apollo spacecraft took this many books. A mind-numbing degree of documentation contributed to reliability, safety, and success. lf one batch of one alloy in one part was found to be faulty, for example, a search could show if the bad material had found its way into other spacecraft, to lie in wait there. |

|

| Inspecting the new hatch, Wally Schirra makes sure his crew cannot be trapped as was the crew that died in the terrible Apollo spacecraft fire. Opening outward (to swing freely if pressure built up inside), the new hatch had to be much sturdier than the old inward-opening one. The complicated latch sealed against tiny leaks but allowed very rapid release. |

|

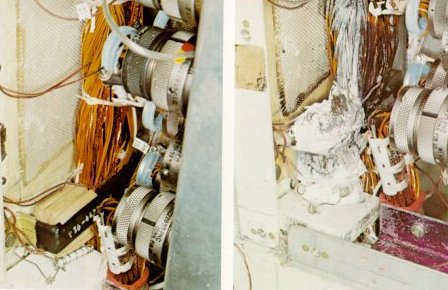

| After the fire, flammability and self-extinguishment were key concerns. In the test setup at right a wiring bundle is purposely ignited, using the white flammable material within the coil near the bottom to simulate a short circuit (left). Picture at right shows the aftermath: a fire that initially propagated but soon extinguished itself. It took great effort and ingenuity to devise materials that would not burn violently in the pure-oxygen atmosphere. lf a test was not satisfactory and a fire did not put itself out, the material or wire routing was redesigned and then retested. |

|

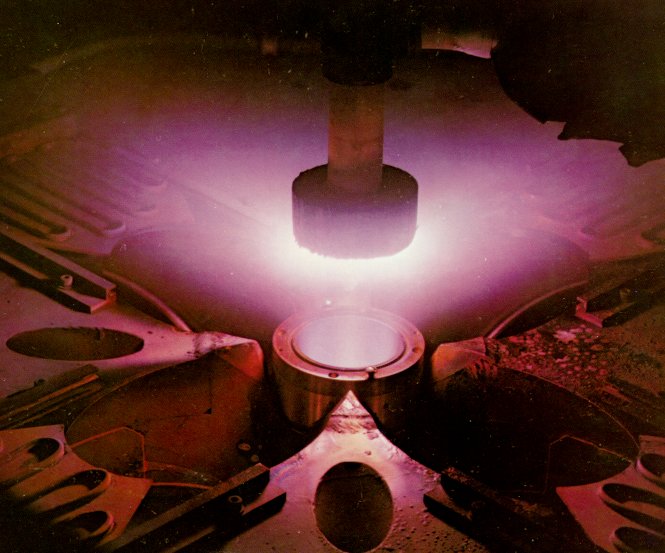

| Seared at temperatures hotter than the surface of the Sun, a sample of heat-shield material survives the blast from a space-age furnace. Machines used to check out Apollo components were as demanding as those in the mission itself, because a mistake or miscalibration during preflight trials could easily lay the groundwork for disaster out in unforgiving space. |

|

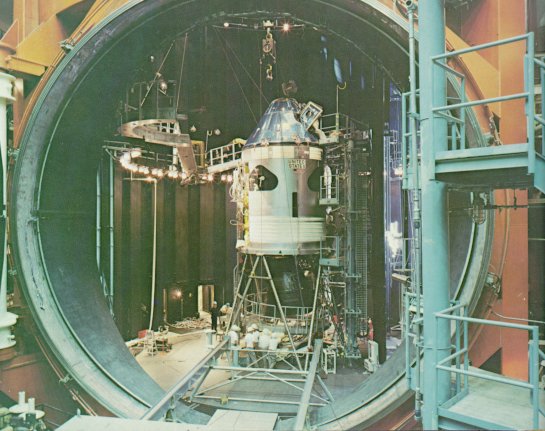

| Meant to fly in a vacuum, and to survive fiery reentry, the command module had also to serve as a boat. Although its parachutes appeared to lower it gently, its final impact velocity was still a jarring 20 mph. Tests like this one established its resistance to the mechanical and thermal shocks of impact, and its ability to float afterward. |

|

| Hitting land was possible, even though water was the expected landing surface. For this, a shock-absorbing honeycomb between the heat shield and the inner shell was one protection, along with shock absorbers on the couch supports. A third defense against impact was the way each couch was molded to its astronaut's size and shape, to provide him with the maximum support. |

|

| Through the portal of a huge test chamber, the command and service modules can be seen in preparation for a critical test: a simulated run in the entire space environment except for weightlessness. In this vacuum chamber one side of the craft can be cooled to the temperature of black night in space while the opposite side is broiled by an artificial Sun. Will coolant lines freeze or boil? Will the cabin stay habitable? |