|

[19] During the first years of camera development we found ourselves in the uncomfortable position of judging a complicated piece of equipment, partly assembled, that had not yet performed its primary function of taking a picture. As our anxiety increased, a difference of opinion emerged between scientists and engineers. Some, though by no means all, engineers argued that the capability of the camera could be measured quantitatively only by a series of tests involving such features as precision of pixel spacing and electrical response of photosensors. The results of the tests were generally shown as tables of figures or graphs. In terms of the contractual requirements, pictures were of little value. Only in a qualitative way did they demonstrate that the numerically defined specifications had been met.

As I pored over the dryly legal requirements of the contract under which ITEK was working, nowhere could I find reference to pictures. My engineer friends sought to reassure me. If each of the components performed according to specifications, a perfect picture must necessarily be the integrated result. I remained skeptical, partly because of my ignorance I was frustrated by schematic drawings and complicated calculations which I only dimly understood. To the hard-working engineers, already immersed in more substantial problems such as components that simply would not work, I must have seemed like the small boy who refuses to believe the Earth is round unless he can travel its complete circumference.

The more the engineers temporized, the more obdurate I became. My resolve was strengthened as others joined the chorus. Finally, at the start of one of our program review meetings, the announcement was made that a picture would be distributed at the conclusion-no doubt an inducement calculated to keep us awake through the technical reports. As that first imperfect image was passed around the table for inspection (fig. 13), the presenter began an apologetic "Let me explain. . " The questions were sharp and numerous. What caused the shading variations? Why were some lines offset? Was this the best spatial resolution we could expect?

The same scene was destined to be repeated many times as the camera design was refined and the manufacture undertaken. For the ITEK engineers it was a choice between the frying pan and the fire. If they failed to produce a recently acquired picture, scientists and supervisors imagined the worst-the end-to-end camera system didn't work. If they did distribute a picture, then every defect was noted, generally with caustic remarks about the cost of the camera and the quality of the image.

Charlie Ross, the ITEK Program Manager, patiently tried to explain that the defects were a consequence of working with a prototype model instead of the actual flight cameras. He reminded us that the cameras were designed to take pictures on Mars, not under the uneven illumination conditions of the laboratory. His protestations sounded weak then, but we doubting Thomases appreciate now that he was right. Jim Martin, Project Manager, probably had some of those early ragged pictures in mind when he said, after viewing the first pictures from the surface of Mars, that the cameras had never worked that well on Earth. Strictly speaking, of course, this was not true, but the apparent difference in quality was dramatic.

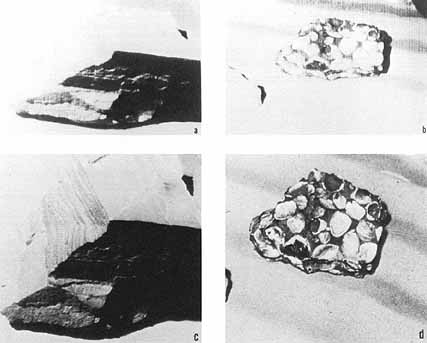

[20] The first extensive science test of the camera was conducted in August 1971. We used a prototype camera, picturesquely referred to, in engineering parlance, as a breadboard model. To the considerable amusement of lTEK personnel, several of my graduate students arrived at the camera facility with a box, one meter square, filled with sediment and rocks. Naturally enough it was irreverently known as Mutch's sandbox. We took pictures of assemblages of sand and rocks both with the Viking camera and with a conventional film camera. To our delight we discovered that many diagnostic features were visible in Viking camera pictures (fig. 14). The images were marred by vertical banding and line mismatch, but these were problems with identified solutions.

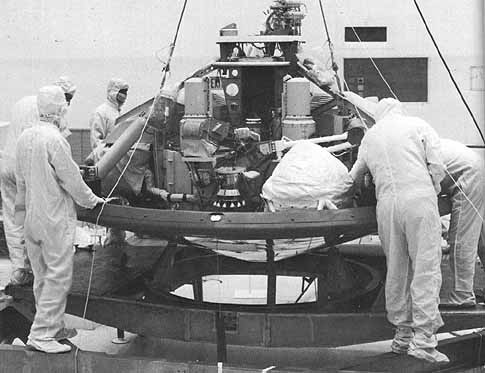

The most important science test occurred in August 1974. By this time the camera manufacture was almost complete. Several units had been delivered to the Martin Marietta facilities in Denver where, eventually, they would be incorporated in the Lander. For several weeks we scientists were permitted the use of one of the extra cameras that, because of minor manufacturing defects, seemed least likely to be designated for the flight to Mars. (This is a continual problem for spacecraft experimenters. The best units are always carefully protected from excessive use.) After months of preliminary campaigning, we were finally granted...

...permission to take the cameras a short distance outdoors, several hundred yards from the Martin Marietta buildings.

Fortunately for the geologists among us, Martin Marietta built its plant in the scenic foothills of the Rocky Mountains where reddish sedimentary strata are tilted on edge and eroded in razorback ridges. We located an area that looked appropriately barren for a Mars analog, especially after we cleared out some dense underbrush (thereby expressing a bias about life on Mars). We spent several pleasant days at the so-called Red Rock site, frustrated only by clouds that temporarily obscured the Sun. The variations in solar intensity produced cosmetically unattractive vertical bright and dark streaking in the pictures, acquired over a duration of 10 min or more.

With the Red Rock tests completed sooner than we had anticipated, the Martin Marietta engineer in charge suggested that maybe we could venture farther afield. I was dumbfounded. Although this was precisely what we had been requesting, we had always been rebuffed with a stern lecture regarding the precious character of the cameras, and the impossibility of operating them without racks of nonportable support equipment. More than once we had peevishly asked how it could be that we were building a camera that could sustain the shock of a landing on Mars, but could not survive a short excursion on Earth.

The offer was quickly accepted. We loaded all the camera equipment and support gear in a rental truck-unaccountably, Martin Marietta seemed to have no vehicles available other than rockets-and started off for Great Sand Dunes National Monument.

To this day I have not figured out how we managed to drive blithely away with thousands of dollars worth of irreplaceable equipment. In a project where even [21] the most trivial events were anticipated by extensive paperwork, the rules seemed to have been suspended temporarily. Several engineers accompanied the camera in the truck. The remainder of the group traveled in private cars, all of us arranging to meet the following day at Great Sand Dunes.

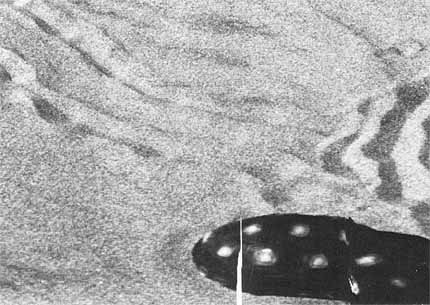

Bill Patterson and I eventually arrived at the monument headquarters. A government ranger confirmed that our truck was already there. From his four-wheel jeep, he pointed out the truck, halfway across a distant sand flat (fig. 15). The truck had followed a downward-sloping embankment of wet sand bordering a shallow stream. Further movement, either forward or backward, was out of the question, so we carried the camera to the crest of a nearby dune, trailing its electrical umbilical cord behind. Leaving the installation in the charge of several volunteers prepared to camp out, the rest of us repaired to a nearby motel.

The next morning, anxious to get as much work done as possible, we were up before sunrise. However, several anxious hours passed before the atmospheric humidity decreased to a level where the camera could operate without danger. (Remember that these cameras were designed to operate on Mars where the atmosphere is thin and the water vapor content very low.) Once in operation the camera and recording equipment continued to work faultlessly, better than ever before. The morning wore on and the pictures piled up.

With the obligatory images completed we turned to more frivolous projects. A box turtle and a garden snake had been obtained from a local pet store and brought along to illustrate biologic form and motion. The turtle was temporarily misplaced-one sobering but unlikely speculation was that he had been consumed by the snake, some ten times smaller-and was subsequently discovered escaping the heat under the truck.

We had no success photographing the snake. Every time we placed it on the hot sand it skittered away before the camera could be turned on. With the turtle we had more luck. Several pictures recorded its artificially distended shape as it moved across the field of view (fig. 16).

For a last picture, I suggested a group portrait. After the usual demurrer that accompanies any request to have your picture taken, everyone lined up and the camera began its slow clockwise sweep. The opportunity for replication was irresistible. Looking into the central slit of the camera, we could estimate when the scanning mirror had passed on to our left. Quickly running around behind the camera we could take our place for a second portrait. In this way I managed to be photographed a record number of seven times (fig. 17).

That evening we convened in a local restaurant for a celebration banquet. It had been perhaps the happiest day we spent on the Viking Project prior to the spacecraft's arrival at Mars. After years of ambiguous tests and reports, we had certified that the cameras really worked. Putting esoteric calculations and graphs to one side, we had said simply "I want to take a picture of that." And each time we asked-close to a hundred times- the camera faultlessly responded.

In a subtle way the success of that day's testing influenced our attitude toward the entire mission. If the cameras worked so well, perhaps it was not unreasonable to assume that other spacecraft instruments and components, plagued by manufacturing problems, might ultimately work just as well. Maybe the reams of paper outlining spacecraft performance had described reality. Maybe, two years hence, we would actually be looking at pictures from the surface of Mars.

From that point on, the testing of the cameras proceeded without incident.

Most of the images were used to verify that the cameras were operating according to specifications. The fabrication of the Lander proceeded, and the spacecraft was transferred to Cape Kennedy for mating with the launch vehicle. During that time the cameras were turned on thousands of times. We cautiously armored ourselves for the bad news that never came. Even following the last hurdle of heat sterilization, the cameras continued to work without fault.