|

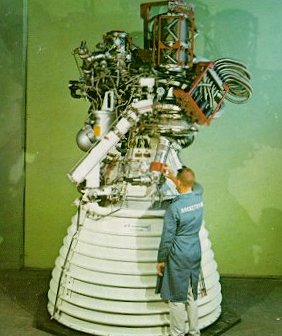

| One of the J-2 engines that power the upper stages of Saturn V. Liquid hydrogen, on its way from the fuel turbopump, is used to cool the walls of the thrust chamber regeneratively. |

|

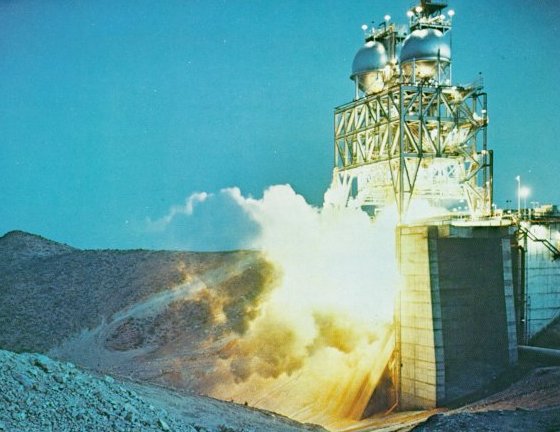

| Thunder echoed in the mountains when a mighty F-1 engine spoke out during qualification. At a remote high-thrust test complex near Edwards, Calif., fuel and LOX were pumped in and tons of water cascaded over the flame deflector while elaborate instrumentation measured the behavior of each new engine. It wasn't flightworthy if it didn't match specs. |

| The first (S-IC) stage of the Saturn V launch vehicle being hoisted into the static test stand at Marshall Space Flight Center. This was the "battleship," or developmental test version of the stage, built heavily to permit repeated testing of flight-version working components. The first three flight S-IC stages were assembled at MSFC and tested in this stand. The massively reinforced construction of the 300-foot-tall stand was essential to withstand the 7.5 million pounds of thrust developed by the stage's engines during static testing. |

| The "pogo problem," a lengthwise mode of vibration recognized in the second Saturn V launch, was speedily solved through mathematical analysis supported by data collected in shake tests. To supplement shake tests in Marshall's Dynamic Test Tower, Boeing quickly erected this tower for special pressure tests at the Michoud Assembly Facility. |

|

| A test at the "Arm Farm". Just to the man's left a skin section representing the S-11 stage is mounted to the Random Motion/Lift-Off Simulator, which can simulate at ground level the swaying of the space vehicle in a Florida storm. A duplicate of the Mobile Launch Tower's S-11 Forward Swingarm projects from the left, carrying the umbilicals that are connected to the skin section. |