|

|

|

|

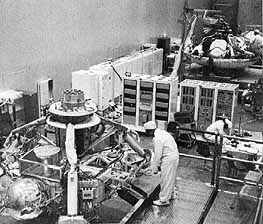

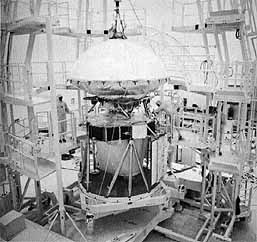

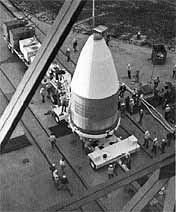

[273] (Viking orbiter 1, top left, is mated to Viking lander 1 at Kennedy Space Center on 8 March 1975. Above, technicians lower the launch shroud over the spacecraft on 27 March. At the left, the shrouded orbiter and lander move toward 31 March mating with the Titan IIIE launch vehicle, for more tests.) |

SOURCE: R. D. Rinehart and H. Wright, " Daily KSC Status (FAX)," memos dated 23, 24, 25, and 26 June 1975; and VPO, "Mission Operations Status Bulletin," no. 7, 23 June 1975, and no.8, 8 July 1975.

|

29 July |

Orbiter precountdown checkout and lander cruise-mode monitoring tests completed. |

|

30-31 July |

Lander computer prelaunch checkout. |

|

1 August |

Composite electrical readiness test completed. |

|

2 August |

Super Zip installed on Viking A shroud. (Super Zip is a linear explosive charge used to seperate the clamshell halves of the shroud after launch). |

|

3 August |

Pyrotechnic ordnance devices installed on Viking A. |

|

6-7 August |

Propellants loaded into Titan IIIE launch vehicle. |